Table of Contents

Pulsed Laser Deposition

The PLD system comprises a ComPex 201 248-nm excimer laser plus optical elements and two vacuum chambers. It is located in Weniger 475. Safety procedures must be observed at all times.

A log of important modifications to the system can be found here. If you want to know why something is the way it is, start here.

Thermionics Chamber

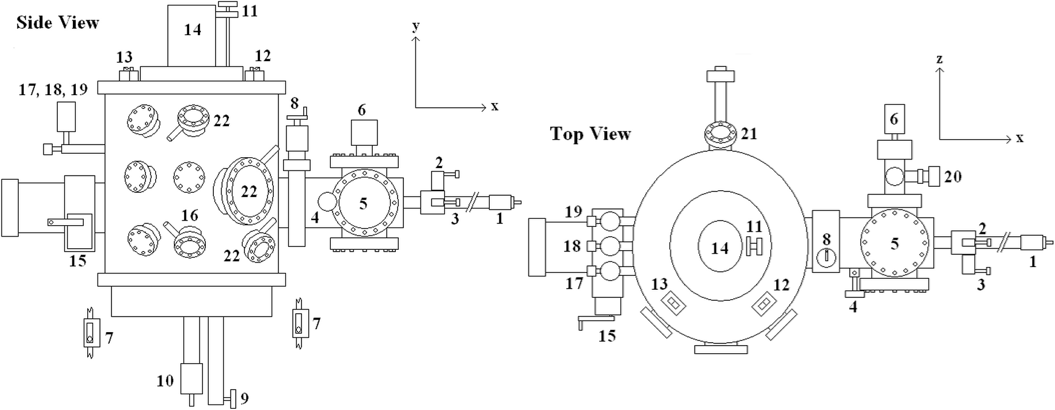

The Thermionics chamber consists of two joined vacuum chambers, the main chamber and the load lock. The main chamber and the load lock are separated by a large gate valve which serves to isolate the two sections. The load lock and the main chamber are each served by two vacuum pumps, a turbo-molecular pump and a roughing pump working in series.

Load Lock

Roughing Pump

The load lock roughing and turbo pumps are manufactured by Alcatel. The roughing pump uses traditional hydrocarbon vacuum pump oil in its operation, and should be replaced every 6 months.

Turbo Pump

The Alcatel turbo pump has a more complicated maintenance schedule. There is no oil sump in the turbo pump like the roughing pump, and so there is no oil to be changed. However, it is essential that the internal bearings are regreased every 5000 Hours. The bearing life specification is 30,000 hours; however this assumes a constant operating condition (100% duty cycle) at high vacuum. The nature of operation for this pump does not meet that specification, since its speed is ramped up and down often. The greatest amount of wear to a turbo pump occurs when its rotational speed is changing, especially at low speeds.

Bearing failure of this particular pump is known to have happened as late as 20,000 hours, and as early as 6,000 hours. This is why the bearing maintenance should be performed at 5000 hours. The turbo pump controller is configured to to remind the user when this interval is met or exceeded.

Main Chamber

Roughing Pump

The main chamber roughing and turbo pumps are manufactured by BOC Edwards. Like the Alcatel roughing pump, the oil on the Edwards roughing pump should be changed every 6 months. However, it is essential that the oil is not hydrocarbon oil. The replacement oil must be Krytox 1506 or Fomblin 06/6. Krytox 1506 is preferred since the Fomblin-type oils tend to leak and seep through seals in the pump, while the Krytox will not. Typically, Krytox is sold by mass rather than by volume like most other oils. To successfully change the oil, 3kg are needed. We use about 3kg/year.

8/2014: Ideal Gas sells Krytox 1506 (new) for $200/kg; Lesker sells Krytox 1506 (new) for $2,500/gal = $312.50/kg @ 8kg/gal.

Krytox 1506 can be obtained about 6x more cheaply by recycling our used Krytox - approx $400/gal = - from Kurt Lesker (but must recycle 2 gal minimum) or from Ideal Gas (1 gal minimum).

5/25/2011: Krytox 1506 costs ~$200/kg.

Do not mix these PFPE oils with hydrocarbon oils; if this happens the pump must be cleaned according to the manual's instructions as these oils are not compatible. This means that they are not soluble in one another, and the material properties will change across the interface, foaming may occur, and the pump will not be properly lubricated. Krytox is used because it is highly resistant to attack by oxygen or corrosive process gasses. DO NOT EVER USE OXYGEN PROCESS GAS WITH HYDROCARBON OILS!

Turbo Pump

The BOC Edwards Turbo pump is an amazing, maintenance-free, wonder pump. This pump has a low pressure limit of 10^-9 Torr, and has magnetic bearings so that there is no hydrocarbon grease vaporizing into the chamber. If the turbine were to suffer an unbalanced build up of matter on it, changing its moment of inertia, the controller will modify the bearing properties along 5 axes (3 translational, 2 angular) such that the turbine always rotates about its center of mass in a balanced way. When the entire system is clean, this pump easily matches it's operating pressure specs, and at times surpasses them.

Substrate heating

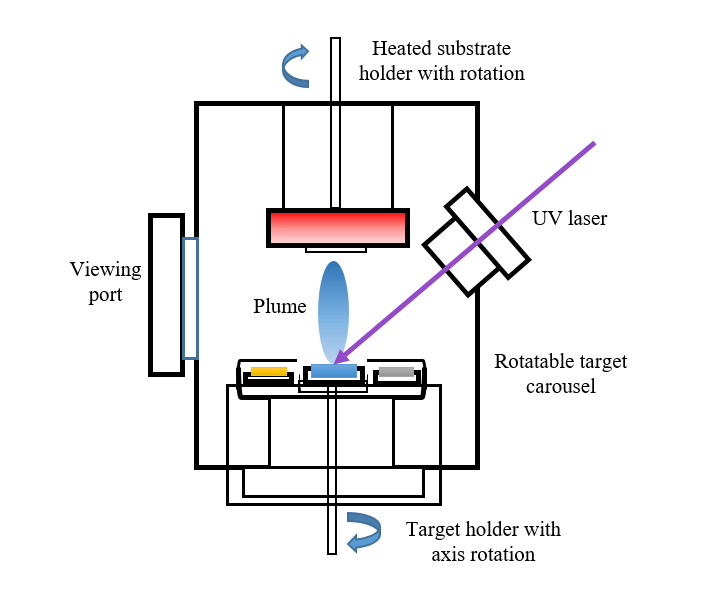

Neocera Chamber

Substrate heating

Power Outages

Thermionics chamber: The Thermionics chamber is set up so that in event of a power failure, the valves between the roughing and turbo pumps will remain closed and the pumps will not turn back on when power is restored. However, the gate valve to the main chamber will be automatically closed, which will prevent the chamber from venting to atmospheric pressure immediately. With the gate valve closed, the pressure should stay in the 10-7 Torr range and very slowly increase until the system is reset.

If you discover that the power has gone out, make sure that the gate valve has closed (by the red indicator light if the power has been restored, or the white spot on the indicator beneath the gate valve motor is on closed). If the valve is closed, you can use these instructions to restore the system. If the pressure is higher than 10-3 or if the gate valve does not appear to have closed, then follow the Pump Down Procedures in the instructions (toggle switch up on silver panel, reset buttons on black panels, wait for the pressure to drop below 10-3 Torr range, then restart Turbo Pumps). Here is a schematic for reference.

Neocera chamber:

Optical Elements

Mirrors

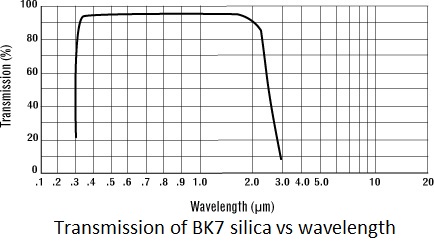

The 3 mirrors used in the optical tower are from OptoSigma (part no. 034-0185 and ). These mirrors are made of a borosilicate glass (BK7) and are designed specifically for KrF laser use at 45 degrees incidence. When configured in this way, the reflectance should be > 99%. The mirrors on the lowest two tiers of the optics tower are arranged at this angle of incidence. The mirror on the highest tier of the optics tower is setup such that the angle of incidence is 30 degrees.

Lenses

The two focusing lenses (one for each chamber) used are of the plano-convex type, and are made of UV grade fused silica. The lenses used have no coatings, and have different focal lengths. The lens used with the Thermionics chamber is OptoSigma part no. 014-1315.

Windows

There are many windows on the thermionics chamber. However, there are two UV grade laser windows. Each of these is mounted in a ConFlat flange. Each of the laser windows is made of fused silica, and measuring with the Coherent power meter, have a loss of approximately 10% at 248nm.

Standard Operating Procedure

Routine Maintenance

The maintenance schedule for the PLD lab is located here.

ComPex 201 excimer laser manual has been taken off-line

Site Prep documentaion for ComPex 201

Changing Gas

Process Tube gas cabinet layout The premixed gas we use is: 0.1% F2, 1.7% He, 3.93% Kr, balance Ne (i.e. rest is Neon), and the SDS is KrF premix SDS

Usually purchased from Airgas, contact can be found by following the Purchasing link

Cleaning/polishing Targets and Substrate Holders

The process we use for cleaning targets/substrate holders includes a series of increasing grit sand paper. The grit sizes range from 200 to 2000 and depending on the density of the material we may start at a smaller or larger grit. For example a soft ceramic target will most likely require you to start with a higher grit (say 800 or 1000) while polishing the substrate holders may require a much lower grit (say 200 or 400) to remove as much of the deposited material as possible. One thing to keep in mind when polishing targets/substrate holders is that the type of material you are polishing may be toxic. A list of toxic metals which need to be disposed of through EH&S is posted on the fume hood and can also be found here.

Cleaning Chamber

Advice from Hiroshi Yanagi (Yamanashi) about cleaning a sulfide chamber (2017). “We use H2O2 for cleaning vacuum chamber, but only when it is terrible. Usually, acetone and alcohol is enough. When you use H2O2 or cleanser, clean up with water, acetone and alcohol. Then bake the chamber. For window cleaning, we used abrasive cleanser for bright polishing of metal surface (not for dish cleaning.)”

Service

Frank Cipolla, ONI Corp, (954) 296-0350, formerly of Lambda Physik, has worked on our laser. Very good service.

email is the best way to contact Frank, frank-cipolla@oni-corp.com